Reference pressure gauge MO-05 from Gidrogazkomplekt, or What is accuracy

An article about our equipment and their features

The article introduces the equipment of the company "Gidrogazkomplekt", developed for verification and calibration of measuring instruments: reference manometer MO-05, presses for checking manometers, measuring complex "POISK", collector KS. Along with the article, an interview with the CEO of the company A.V. Heide, in which he reveals the features of this unique equipment and talks about its areas of application.

In every industrial or residential facility, devices for thermophysical measurements are used. To ensure the uniformity of measurements, it is necessary to periodically verify and calibrate measuring instruments, using standard instruments for these operations.

There are a large number of foreign manufacturers that offer reference measuring instruments, but their cost is quite high, and the delivery (or repair) time can be up to two months or more.

Manometer MO-05

The digital pressure gauge MO-05 (Fig. 1) of Russian production refers to the reference devices that have no analogues among foreign samples. Moreover, today he himself begins to generate analogs. Its main purpose is to accurately measure the excess pressure of liquids and gases, as well as the vacuum pressure.

Figure: 1. Manometer MO ‑ 05: model with a limit of the basic reduced error of 0.025%

The manometer can measure pressure (vacuum) from –0.1 to 60 MPa and has up to six subranges (according to the standard series). The produced models measure:

- pressure 6; 10; 16; 25 and 40 kPa;

- pressure (vacuum) 100 kPa; 0.04; 0.06; 0.1, 0.16 and 0.25 MPa;

- pressure (vacuum) 100 kPa; 0.4; 0.6; 1.0; 1.6; 2.5 MPa;

- pressure 2.5; 4; 6; ten; 16 MPa;

- pressure 10; 16; 25; 40; 60 MPa.

The user can choose one of the sub-ranges and the unit of measurement himself: Pa, kPa, kgf / cm², MPa or mm Hg. Art.

Taking into account that each manometer has several units of measurement and up to six dedicated measurement ranges, it can be calculated that five versions of the MO-05 manometer replace 60 model manometers. In other words, the MO-05 reference gauge is much more efficient and cheaper to operate than other reference gauges, which are usually designed for a single measuring range.

MO ‑ 05 manometers may have the limits of the basic reduced error of 0.025; 0.05; 0.1; 0.15; 0.25 or 0.4%, which meets any consumer demand for accuracy and price.

Pressure readings are displayed on an LED array with varying intensity (user selectable). Units and subranges are also illuminated by LEDs.

Autonomous power supply of the manometer from three AA size lithium batteries allows using this device for field work. Time of continuous work without changing batteries is more than 300 hours.

MO-05 is equipped with a USB connector, through which the pressure gauge is connected to a personal computer, after which information is displayed from the device on the monitor screen. On the website of the company "Gidrogazkomplekt" in the public domain, you can find a program that automates the verification of dial gauges and prints out the verification protocol. With this program, up to six pressure gauges located on the same pressure source are simultaneously checked. Also on the company's website there is a publicly available data exchange protocol between MO-05 and a PC, which allows the use of a pressure gauge for work in automated technological processes.

Separately, we note that when MO-05 is connected to a computer, the pressure gauge disconnects the power from the batteries and connects to the power supply from the PC, thus saving battery power.

Convenient user interface (with the help of two buttons the entire range of functions is performed), sound protection against overload, flickering of indicators when the batteries are low - all this makes it possible to work with the device without special training.

The front of the gauge has an infrared window for adjusting the upper sub-range limit. In this way, the inevitable decrease in accuracy can be compensated for, ensuring long-term stability of the instrument. The range adjustment is performed by a qualified technician, breaking the manufacturer's seal and using the separately supplied remote control.

Pneumatic Presses

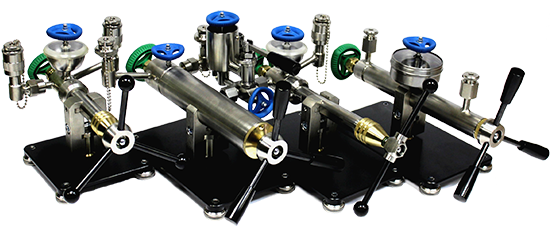

The Gidrogazkomplekt enterprise produces a wide range of portable and stationary presses for checking and calibrating pressure devices (Fig. 2). A series of pneumatic presses is capable of creating pressure (vacuum) from units of pascals (for example, a PS-50 press for checking draft gauges) to 2.5 MPa (a PUM-6M press, which can also create a vacuum of –0.095 MPa).

Figure: 2. Presses for checking and calibrating pressure devices

A series of hydraulic presses that are capable of operating in gaseous media, creating pressure and vacuum, is represented by units 2113M, PUM-60, PUM-40M, PUM-100M. The maximum pressure that some of the models create is 100 MPa.

All presses are made of stainless steel and can work with different media: water, oil, kerosene, etc.

For the use of hydraulic presses when filling large volumes, a pump mounted on the PUM series presses is intended. These presses have two points of connection for pressure gauges with self-tightening chucks, which do not require the use of keys to secure the instruments.

A stationary press weighing 14 kg can create pressures up to 120 MPa.

All presses are equipped with a seal - standard rubber rings, which can be easily replaced if necessary.

Measuring complex "POISK"

To carry out metrological work on-site, the company's developers have created a portable multi-range measuring complex "POISK" (Fig. 3), which includes: a press for creating pressure PUM-60M, up to five MO-05 pressure gauges, a set of adapters, a tool, instructions and napkins. The entire set is packed in a sealed case. Each MO-05 pressure gauge is stored in a separate protective case. Measuring complex "POISK" allows checking both in stationary conditions and directly at the facilities.

Figure: 3. Complex "POISK"

The consumers of POISK today are enterprises of the oil and gas complex, the Ministry of Emergency Situations, the Ministry of Internal Affairs, the Ministry of Internal Affairs of Russia, the structure of the Russian Railways, etc.

Collector KS

During verification, it is often necessary to compare whether several pressure gauges used at the same facility show the same pressure. The collector of the KS series helps to accomplish this task (Fig. 4). The collector can be connected to any pressure source through a connecting sleeve or directly to a PUM-60M (PUM-40M) press. It is equipped with self-tightening chucks and, depending on the model, can have from three to six fittings for simultaneous connection of pressure gauges. During transportation, the collector folds like an accordion, in addition, it has a low weight and dimensions, which is convenient for field work. The collector KS is made of stainless steel and can be used for any media that is not aggressive to 08X18H10T steel.

Figure: 4. KS manifold with pressure gauges connected to the press to create pressure

Separately, it should be noted that all products manufactured by the Gidrogazkomplekt enterprise can be manufactured in an oxygen version, that is, to work with oxygen.

Instead of an afterword. Interview with Andrey Vladimirovich Geide, General Director of Gidrogazkomplekt LLC

LLC "Gidrogazkomplekt" is a company with traditions, founded by specialists of the famous Moscow plant "Manometer". The verification equipment manufactured at this enterprise is used both in Russia and abroad. And yet, hearing how the company's CEO proudly calls these instruments “masterpieces of metrological equipment,” we were truly intrigued.

ISUP: Tell me, which consumer is your product mainly designed for? In which industry are your reference gauges most commonly used?

A. Heide: Good question. Our consumer is mainly metrologists of various enterprises, industries, oil and gas industry, law enforcement agencies, metrological centers, etc. I would even say this: the buyer of our equipment is those organizations that have a need to measure, control and create pressure, and of course, who is involved in the calibration of pressure devices. The buyer is not easy, I would even say conservative, and this is understandable. Everything related to pressure is connected in one way or another with money, and most importantly, with the health of personnel working with pressure. I will name only a few buyers of our products: the Russian Emergencies Ministry, the Russian Armed Forces, the Ministry of Internal Affairs, Gazprom, Gazpromneft, Surgurneftegaz, Rostest-Moscow, TsSM of various regions, the Kurchatov Institute, and may not be offended by hundreds of our other buyers who are all dear to us.

ISUP: Can we say that your devices are an inexpensive and high-quality solution?

A. Heide: The slogan of our company is: “We make expensive devices, but we sell them cheaply”. As I said, our customer is quite conservative in the choice of equipment. If the equipment that we produce was of poor quality or did not work well, then our enterprise would have ceased to exist long ago. The creative approach of our developers and designers, who do not just serve their working hours, but create truly unique equipment, I would even say, masterpieces of metrological equipment, as well as a responsible attitude to the performance of their duties of our entire workforce allowed us to organize the production of high-quality products at a fairly low price...

ISUP: The MO-05 manometer is produced in five versions. How do they differ from each other?

A. Heide: Exclusively for measuring ranges and accuracy class. The first measurement option has 6 measuring ranges; ten; 16; 25; 40 kPa. The second option is available with measuring ranges of 0.04; 0.06; 0.1; 0.16; 0.25 MPa. Third option: 0.4; 0.6; one; 1.6; 2.5 MPa. The fourth option: 2.5; 4; 6; ten; 16 MPa. Fifth option: 10; 16; 25; 40; 60 MPa. Thus, five pressure gauges cover the entire standard according to GOST pressure range from 6 KPa to 60 MPa.

ISUP: How often is MO-05 verified - an exemplary instrument used to calibrate conventional pressure gauges?

A. Heide: MO-05, like any measuring instrument, has a calibration interval. For MO-05, the intervals between verifications are one year for devices with a basic permissible error limit of 0.025 and 0.05%; two years - with the maximum permissible basic error of 0.1 and 0.15%; three years - with the maximum permissible basic error of 0.25 and 0.4%. For the verification of such devices, there is a special technique developed by our specialists and approved by the All-Russian Scientific Research Institute of Metrological Service (VNIIMS).

ISUP: You produce oxygen pressure gauges - devices that help regulate the pressure when supplying oxygen. It is known that oxygen is explosive, which means that the design must be special. What is special about your oxygen pressure gauges?

A. Heide: Many manufacturers have an additional inner membrane in the design of the sensing element, the space between the outer and inner membranes is filled with a certain substance. In the event of damage to the outer membrane, this substance flows out and falls on the degreased surface of the oxygen manometer, and this is unacceptable. We use non-filling sensing elements. Generally speaking, few people make digital oxygen pressure gauges.

ISUP: Can you say something additional about the press of your production?

A. Heide: Our company has developed a line of presses with an extended service life of the PUM series. The weak point in any press is the pressure cut-off point and the wear of the seals on the piston that creates the pressure. We managed to find technical solutions that significantly increase the service life of problematic units. The sales of our presses are growing every year, probably due to the number of presses already sold. In addition, there are presses that have no analogues. For example, a commercially available press PUM-100M with a weight of only 5 kg creates a pressure of 100 MPa (let me remind you that the same pressure under water at a ten-kilometer depth, for a minute), while the pressure gauge is connected to the press without the use of wrenches, by hand until lightly squeezed , using self-tightening chucks.

ISUP: How does the Gidrogazkomplekt press differ from similar products of other companies?

A. Heide: First, it works not only with oil, but also with water. Secondly, hydraulic presses of the PUM series are equipped with self-tightening chucks, which makes it possible to ensure reliable connection of the pressure gauge to the press without the use of wrenches. Third, they are very reliable and durable. Fourth: the PUM-100M press with a weight of 5 kg creates a pressure of 100 MPa, a huge pressure, as already mentioned. Finally, they are inexpensive.

ISUP: How compatible is your company's pressure gauge press with measuring equipment from other manufacturers?

A. Heide: In Russia, the standard connection M20 × 1.5 is used, but other standards are used abroad, as a rule, these are inch threads. We produce a set of adapters especially for such cases.

ISUP: How qualified should a specialist be to carry out verification using your equipment?

A. Heide: A specialist must be certified. It is prohibited to work with pressure without certification. Our equipment is easy to use, and there are training videos on our website. The user interface of the MO-05 is so simple that even a child can figure it out.

The article was published in the journal "ISUP", No. 6 (60) _2015

LLC "Gidrogazkomplekt", Moscow,

tel .: +7 (495) 255-2296,

e-mail: ooo.gidrogaz@yandex.ru,

gidrogaz.ru